Industrial Metal Fabricators

JPen are engineering and metal fabricators situated between Nottingham and Derby in the East Midlands, the heart of the UK.

The company creates and supplies high precision, quality, bespoke metal fabrications to industries throughout the entire country as well as Europe. Tailor made products are fabricated to individual customer requirements from mild and stainless steel, in addition to cromweld, aluminium and copper.

Jpen produce a formidable array of products, some categories are listed below, please click on an icon to see actual examples.

Metal Fabrication Services

The strong reputation of JPen is built upon its unfailing track record for successful project completion on time and within budget. With the use of regular surveys, customer evaluations have rated from satisfied to very satisfied regarding products and services offered by JPen.

Skilled Metal Fabrication Workers

The current climate for the metal fabrication industry shows a shortfall in the number of skilled welders, plate fixers, fettlers and machinists. JPen are very fortunate to have a full and growing compliment of qualified and experienced staff covering all skillset requirements for any and all fabrication project. Presently the company is continuing to run multiple apprenticeships, training and developing young colleagues under the guidance of experienced master engineers. JPen is focused on imparting its wealth of knowledge and experience to secure both corporate longevity and to develop even greater output to support increasing industrial demand.

Turn-Key Project Management Services

The systemisation and modularisation of core company engineering methods enable JPen to offer OEM installation options alongside a very popular full project management service. The previously mentioned workforce, with extended experience, has transferable skills that continually generate a responsive attitude producing benefits welcome to the customer.

The well integrated project team function as an efficient driving force behind all types of design, build and installation procedures, with traceable accountability and first rate communication. Clients are continually kept in the loop for milestone stages to ensure any client parallel development activities and or installations are kept on course.

Metal Fabrication Facility Space

The main JPen production facility currently encompasses just over a 10,000m2 production floor space. The construction centre features isolated sections for stainless and mild steel to thoroughly eliminate any likelihood of cross contamination. Presently the production area has 2 gantry cranes the first has a maximum load rating of 10 tonnes and the second is 5 tonnes.

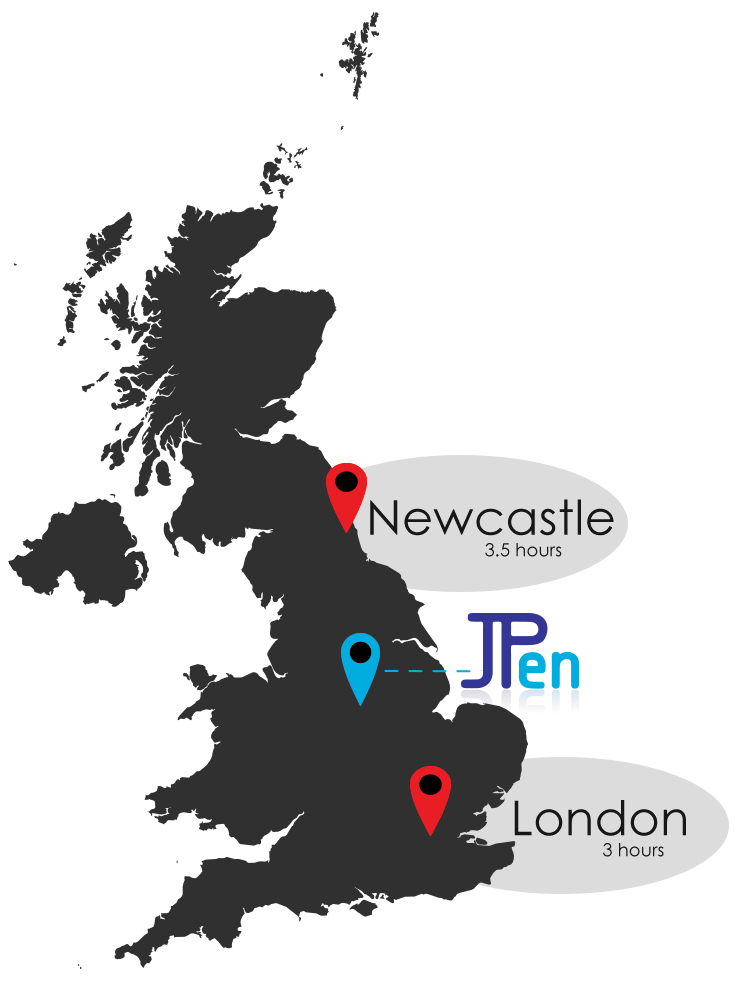

Metal Fabrication Site Location

With the facility being located in Ilkeston, JPen is in a prime position for greatly improving the transport logistics for both outgoing products and incoming supplies. Junction 25 of the M1 motorway is approximately 4 miles away from the main base. This major route feeds all other primary routes for the North and South of the UK. There is also a supporting rail network into the Stanton industrial area for the moving of large containers by rail freight. Transporting by road to the centre of London can be achieved in under 3 hours, with almost the same time frame applied to Newcastle upon Tyne.

Quality Management Systems ISO 9001 & BSEN 1090 Execution level 3

The company has active certification for ISO 9001 (2015) and continues to maintain all requirements for this set of control standards. In addition, the company has BSEN 1090 Execution Class level 3 which incorporates all other class requirements for steel fabrication and allows for products/construction to be used in buildings containing hazardous substances or processes, buildings exceeding 15 stories in height and grandstands accommodating more than 5,000 spectators.

Plasma Cutting Metal Services

Utilising very modern and powerful equipment, JPen has the capability to virtually print to order intricate parts, pieces and sections for use in multi-form fabrications as well as bespoke individual pieces. CNC powered plasma cutters backed by industry recognised CAD tools controlled by talented design staff work together to enable high class efficiency and precision accuracy with the added bonus of reduced production times. In many instances the chief engineer is able to commission a task from a design workstation (PC) as simply as printing a document to a regular printer, only in these cases the media (steel not paper) is a little more expensive.

Architects and Civil Engineers

The strong reputation of the company has bought the attention of numerous architects and civil engineers, consistently recognising JPen for its high quality products as well as the quick, reliable service delivered for each project. With the aforementioned BSEN 1090 (EX-3) qualification at hand, the door has been opened to work on a considerable number of intricate and large scale projects, frequently utilising the company’s entire business skill set. Through positive, well experienced direction customers JPen continues to win contracts from both new and existing customers on a regular basis.

Health and Safety / Environmental Responsibility

Presently JPen is working with ISO consultants to become ready for audits for the standards of ISO 45001 (Health and Safety Management) as well as ISO 14001 (Environmental Management Systems.

Work safety at JPen is taken very seriously, that is why the company is under consultation management to become 100% ready to pass the ISO audit inspection for the plant facility. In tandem all aspects of the business are being modified to eliminate avenues of environmental impact and present a neutral footprint within the industrial sector. At this time the company fulfils all local environmental requirements for manufacturing, JPen is committed to surpassing all the international requirements, thus setting high standards that show customers our will to be responsible and accountable in all aspects of the business.